Anchor hardware systems: "closed" vs. "open"

Traditional anchor hardware, at least in most parts of North America, has typically been some combination of chain links, quick links, and/or welded rings.

One term for these is a “closed” hardware system, because the bottom link (where the rope needs to go for you to rappel or be lowered) is closed.

Examples of CLOSED anchor hardware:

Quicklinks with chains

Quicklinks with rings

Fixe vertical anchor. These are great for multi pitch climbs, but not necessarily for single pitch routes. Strong though it is, when that big ring at the bottom wears out the entire anchor may need to be replaced.

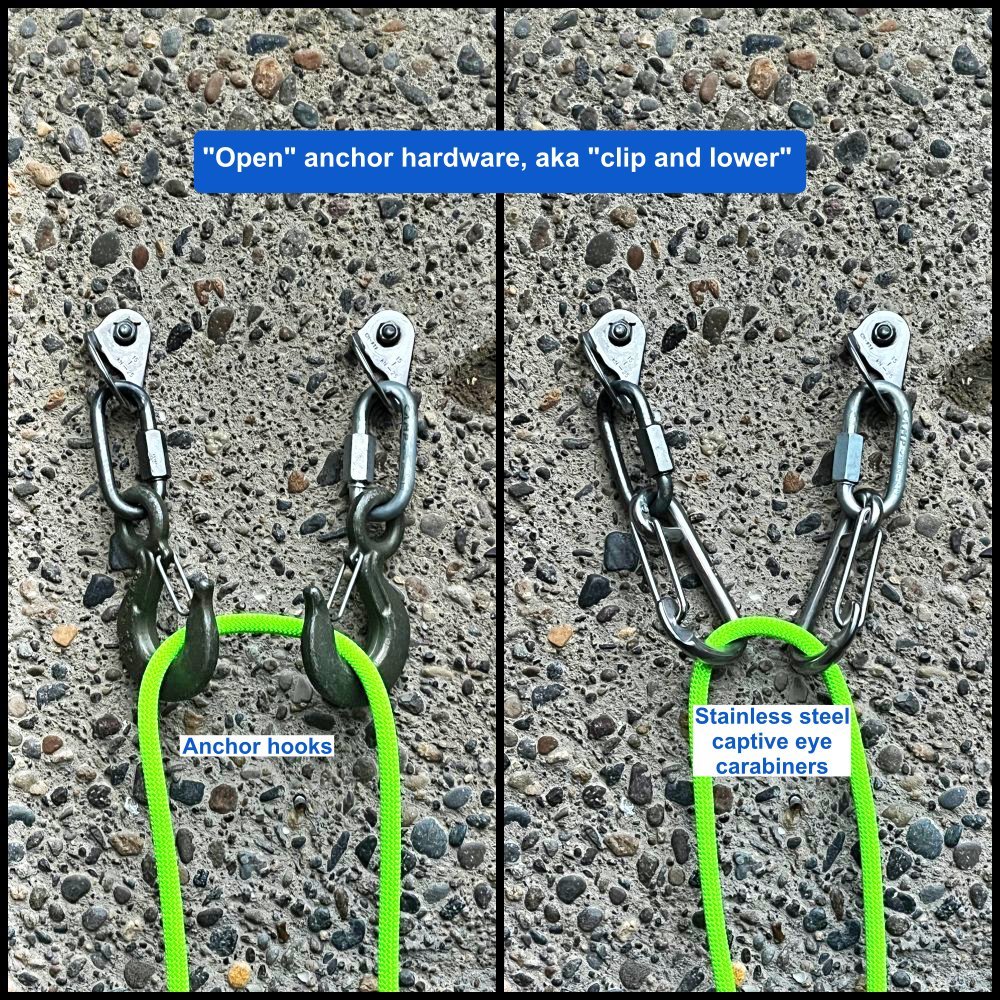

However, for single pitch routes, an increasingly popular anchor is an “open” hardware system, also known as a “clip & lower”.

Examples of OPEN anchor hardware:

Anchor (aka “Mussy”) hooks.

“Captive eye” carabiners, which are theft proof (unless you’re a scumbag with pliers.) Many rock gyms have these on all the perma-draws. Those are galvanized steel for indoor use. Stainless steel is strongly preferred for outdoors.

To be clear: generally, it’s best practice with any kind of anchor hardware, closed or open, to toprope on YOUR gear and use the hardware to lower off only for the LAST person. More on that below.

Because the anchor points are “open”, and often facing away from the rock, it is remotely possible to unclip the rope if you were to climb above them and fall at some weird angle. It appears that this was a factor in a tragic accident in the United States in 2023; more on that below. If you stay below the anchor and put a steady load on it as you would when lowering, it should not be a problem.

The best use of open hardware: lowering off one pitch routes. A multi pitch route, closed hardware is preferred, because you were only attaching to the anchor or rappelling down. To rappel you need one end of the rope available, which you thread through the anchor and pull rather than clipping. So, there's no reason for open hardware on a multi pitch.

Note the anchor hooks and carabiners both face outward, not opposite and opposed. There’s a reason for this, more on that below.

Close up of stainless steel captive eye carabiners. About $6 each. Not CE rated, but 3/8 inch / 10 mm marine grade stainless steel, with a breaking load of nearly 5,000 pounds / 2,250 kG. That’s #SuperGoodEnough for a lower off anchor! These particular ones have gates that are quite stiff, which makes accidental backclipping much harder. That’s good!

I got these from usstainless.com.

Ram’s horn / pigtail open anchors

Another style of open anchor hardware is a “ram’s horn”, aka pigtail. More common in Europe, but still quite rare in the United States. They are being used in a few areas, so I thought I’d mention it.

These are typically made from 10 of 12 mm stainless steel rod, and cost about $10 each. They also come in titanium, which wears out faster than stainless steel, but is good for coastal areas. And no, it doesn't twist your rope.

You can get them from team-tough in the US or in Europe from bolt-products. (Reminder: there are no affiliate marketing links on my website. I post links like this as a convenience.)

Simply flip the rope and around each horn and lower off. Does it look sketchy to you? Could the rope magically unclip itself from both horns at once? Pretty much impossible; it’s close to getting-hit-by-lightning unlikely.

Apparently in Europe it's quite common to have just a single horn to lower from, but personally I'm not too excited about that. Here's an accident report from the Austrian Alpine Club about this failing during a rappel, which I'm pretty sure was from just a single point, and not two separate pigtails. The club mentions there have been several accidents related to these but I don't know any other details. Remember, Americans like moi prefer redundant anchor points.

Again, the best use of these is LOWERING from single pitch routes, not as rappel anchors. (Using these doesn’t make much sense to me on multi pitch rappel anchors, because you're already untied from the end of the rope, so a closed ring seems lots more secure.)

From the article:

“After a few serious climbing accidents, we (Austrian Alpine Club) have to advise against using pig tails (see picture) for abseiling. In the event of jerky loading and unloading, the rope can detach completely from the steel bracket!”

Here's another accident report from Austria, not sure if it covers the same incident or not. It's in German.

“The sow tail, which is designed as a deflection hook, is a system that is open at the top and requires correct insertion of the rope as well as the subsequent downward load. If the rope is moved up over the sow tail, it can be unhooked. This danger must be taken into account, especially if the belay with pigtail is positioned below the climber's tie-in point.”

Note the photo below where these are used as a pair. This makes it more secure than just a single one.

image: https://climbingboltsupplies.com/products/bolt-products-rams-horn

Here's an outstanding video from our friends at HowNot2.com showing different ways to rig anchor hooks, some potential problems, and lots more. A good instructional segment starts at 8:30.

Check out this YouTube video by Bobby Hutton (part of the team at HowNot2.com) for more on the ram’s horn. Note in this video he has a very interesting vertical arrangement to the anchor points, rather than two horizontal components. Check the video to learn the benefits of this system.

OK, got it. So what? What’s cool about open hardware for single pitch routes?

My buddy Ryan Jenks at HowNot2.com has a great blog post on this, so I'm gonna borrow a few paragraphs from him (used with permission, of course.)

“Closed systems require climbers to untie their tie-in knot to connect the rope to the anchor to clean a route. This can be dangerous if a climber misses a step or gets confused. Speaking of steps, closed systems require a lot of them. Cleaning a route with a closed system anchor demand knowledge, focus, memory, and organization. Missing any step can be catastrophic. Closed systems make it impossible for the rope to come out of the anchor, this is their main benefit.

Open systems require less knowledge and memory because they remove at least 8 steps when cleaning a route. We think that makes them safer. Open systems also ease traffic jams on popular routes because it is much faster to clean them. The disadvantage of open systems is that it's not impossible for the rope to come out, it's only extremely freakishly unlikely.”

Ryan also put together this great spreadsheet/list on his blog post of comparing the steps involved with different systems. Hint, fewer steps are usually better!

image: https://www.hownot2.com/post/mussy-hooks

Let's talk about anchor hooks, the most common flavor of open anchor.

Below is a photo of some hooks recently retired from one of the most popular single pitch routes probably in all of the United States, “5 Gallon Buckets” at Smith Rock Oregon. Yikes, those look pretty scary, don't they? (Sidenote, I‘ve lowered off these exact same hooks.)

I'm using the term “anchor hooks”, because that’s preferred by the American Safe Climbing Association, rather than “Mussy”. See their comments on this below.

Here's why anchor hooks are great.

They cost about $9 each.

They’re attached with a simple quick link to the bolt hanger, so the bolt never needs to be touched. Just open the quick link and put in a new hook. Fast and easy to replace.

Even these worn out hooks both break tested over 60 kN!

Very long lasting. I have no idea how many thousands of people have lowered off these hooks, but they lasted for many seasons on a very popular route.

Side note: Anchor hooks are typically placed so both gates are facing OUT from the rock. Yes, this means they are not opposite and opposed. Why? See next paragraph.

photo credit: https://www.mountainproject.com/photo/122999681

A cautionary note on anchor hooks

In autumn 2023, there was a fatal accident in Alabama. It involved a beginning climber who was cleaning an anchor hook anchor, that had a locking carabiner added to minimize wear on the hooks. The carabiner was removed, somehow the rope unclipped from the hooks, and she fell.

Short version: for anchor hooks, do NOT add a carabiner on the anchor for the rope. If you do toprope through your own equipment, extend quick draws or slings BELOW the level of the hooks, and put the rope through your own gear that way. This reduces, but does not eliminate, the risk of the above accident happening again.

Also, NEVER have someone clean an anchor who is not 110% solid on the correct procedure. The proper learning sequence should be: 1) instruction on the ground, until the person can demonstrate several times in a row the correct sequence. Then, 2) doing it with an instructor off the ground, hanging at the actual anchor, where they can be directly supervised. (This means NOT yelling instructions from the base of the cliff!)

Here’s an analysis of the accident from IFMGA Certified Guide Karsten Delap.

Here's another video from Karsten showing a few different methods of building an anchor with your own gear, and transferring to the anchor hooks when it's time to lower off for the last person.

So, why are anchor hooks usually placed with both gates out, and not opposite and opposed? I asked the American Safe Climbing Association, and they said:

“Anchor hooks are placed with gates out for a couple reasons. If opposed the inward facing hook tends to gouge into the rock and scar it up, along with orienting strangely to wear much faster on the nose or even get pushed into the bottom of the wiregate. If they are extended with chains to lay flat and opposed the rope gets pinched behind the hooks and wears unnecessarily/grooves the rock.

If the hooks are placed in very overhanging terrain this ceases to be a problem, but the opposition of the hooks still causes more friction on ropes and the hooks themselves, so we feel that because they are being used for lowering and the climber will always be beneath them gates out is the ideal configuration.

Obviously this all is dependent on the climber never being above the hooks - trying to clip into the system from the top of the cliff then downclimbing to set a toprope being a particularly dangerous scenario. There are many ways to dangerously misconfigure any anchor system and there will be no way to protect against all of them, but it is important that when a equipper places any type of anchor they consider how they are normally accessed. We have some guidelines on our Lower Off Initiative page detailing what to do if climbing above, etc.

Also, just as a matter of language, we refer to the CT wiregate hook as an "Anchor Hook" and the old style ones with the crappy gate as a "Mussy Hook", this is commonly misused but we stick to it as there is a difference and the Anchor Hook is purpose built for climbing applications with a stainless steel wiregate.”

Since we're talking about strength of horrendously worn out anchor hooks, let's look at the breaking strength of a NEW anchor hook, a steel carabiner, and a ram’s horn. (Data from HowNot2.com)

Keep in mind this is for a single pitch top rope anchor, where the forces will hardly ever be more 4kN.

New anchor hook: about 72! kN

Steel “gym” carabiner: about 49 kN

Ram’s horn: about 22 kN

Your climbing rope will break in about 14 kN, so anything stronger than that and you're good. In summary: way more than #SuperGoodEnough!

Here's a visual I like. 1 kN is about 100 kg, or 220 pounds. The way I like to think of it is the average weight of an NFL football player. There are 11 players on offense and defense playing against each other, so any point during the game there's 22 players on the team. Imagine 22 NFL football players all hanging from ONE 8 mm Dyneema sling that's rated to at least this amount. Or in this case one Ramshorn. To really get ridiculous, think of 72 football players all strung together, hanging off of an anchor hook.

Yep, that's plenty strong enough for your climbing.

The American Safe Climbing Association (ASCA) fully supports open anchor hardware for single pitch routes.

“The ASCA is committed to standardizing clip-and-lower style anchors on high traffic, single pitch routes across the country. In 2022 we provided over 5500 Lower-Offs through our Lower-Off Initiative. The majority were ClimbTech anchor hooks, but some ss and titanium went to wet/coastal areas. Along with the hooks, we supplied over 6000 quicklinks for attachment to existing anchors.”

Here's a photo from their website. (Note the hooks are both facing OUT away from the rock.) The ASCA started what they call the “Lower-off Initiative”. Hint hint: donating to a great organization that's actively trying to save your life is a great idea.

I asked them on Facebook to clarify their stance on lowering on open anchor hardware. Is it for everyone or just for the last person? Here's what they said:

“Our general recommendation is that everyone except for the last climber toprope/lower off personal gear, and the last climber in the party lowers off the fixed hardware. That being said - the gear we provide is robust and long lasting so don't feel bad if you go straight through the steel because you have concerns about a toproper not making it to the anchor or being proficient enough to move the rope over to the fixed lowering hardware. Our goal is less accidents.”

image; https://safeclimbing.org/lower-off-initiative