Does an MA system put more load on the anchor?

Warning to non-enginerds: this question gets a little technical, feel free to skip it if you want. The takeaway is YES, it usually does, so make your anchor extra stout. If you want to know why, read on.

Ahh yes, this is a very interesting question, and one subject to much debate on the inter-webs.

Lots of folks think that an MA system always magnifies the load on the anchor. For example, if you have a 2:1 system lifting a 100 kg load, then the anchor is holding 200 kg. A 3:1 system, the anchor is holding 300 kg, etc.

This is NOT correct!

Theoretically, an MA system does not put more force on the anchor.

In the real world, friction in your system actually LOWERS forces on the anchor.

Let's first have a closer look.

The higher the MA of the system, the more force goes to the anchor.

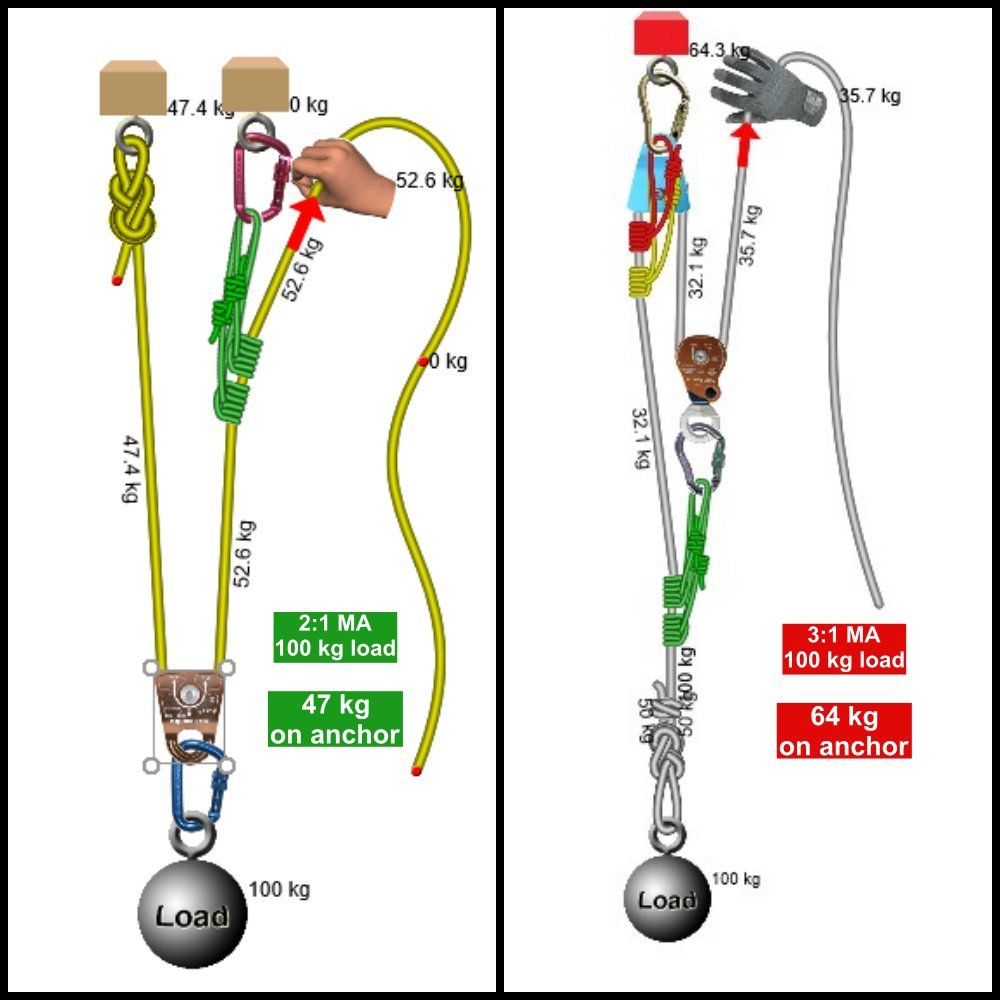

Let's have a look at the diagram below, made with the clever software vRigger. Assuming no friction in the system, and a load of 100 kg, there's quite a large difference in the load that gets transmitted to the anchor with the 2 to 1 compared to the 3 to 1. This is a pretty straightforward rule that applies to all MA systems.

Why is this? The lower the MA of the system, the more of the load you’re supporting with your hand, and the less goes to the anchor. With a 2:1 system, about half the load is on your hand and half is on the anchor. With a three to one system, roughly 1/3 of the load is on your hand and the other 2/3 of the load is on the anchor.

made with vrigger software

A redirect on the anchor for pulling increases the force on the anchor.

This is a great rule to keep in mind when you want to reduce forces on your anchor, such as crevasse rescue with one buried deadman picket.

Check out the example below with a 2:1.

With the standard set up on the left, about 0.5 times the load goes to the anchor.

When you redirect as shown on the right, about 1.5 times the force of the load goes onto the anchor. That's a big difference!

made with vrigger software

In the real world, friction can increase force on the anchor.

Let's revisit Sticky, who is pulling a simple 1:1 pull, redirected through the pulley high up in the tree. Only this time, instead of the tree branch conveniently hanging out over the edge of the cliff, the tree is set back, so the rope is running over a rock ledge. For this discussion, let's say that Sticky needs to pull with an extra 50 pounds of effort to overcome the friction of the rope running over the ledge. For her to lift the 100 pound load, she needs to generate 150 pounds of effort.

If she pulls with 150 pounds of effort to raise the load, that means there is now 150 pounds on the strand coming out the other side of the pulley. Which means the anchor is holding 300 pounds rather than 200 pounds. Remember, when you redirect your pull, that redirect point will receive twice the force that you apply.

Note that this does not have anything to do with the actual mechanical advantage of the system. Instead, it's an example of how friction in your hauling system can result in increased forces on your anchor, regardless of the mechanical advantage you’re using.

However, friction works differently in a crevasse rescue scenario. Here, the friction in the system reduces the final load that’s transmitted to the anchor.

One person from your 3 person rope team fell into a crevasse. The rope going to them is cut deeply into the crevasse lip, adding a lot of friction.

You have 50% efficient carabiners instead of 90% efficient pulleys.

On your alpine climb, you’re using small diameter, stretchy dynamic ropes.

To rescue your buddy, the two people on top need to pull extra hard to overcome rope stretch and friction, compared to a theoretical frictionless environment. However, this extra pulling force is dissipated as heat, and does not get transmitted to the anchor.

This was NOT very intuitive to me! I’ll admit I got it wrong when I first wrote this article. I have since been corrected by an alpinesavvy fan, and I’m grateful for his constructive suggestions to improve this article.

I think it's a better show than a tell, so check out the diagrams below.

These diagrams are from the incredibly helpful “mechanical advantage calculator”, from alpinerecreation.com. Highly recommended and super easy to use tool for checking your real world MA of different rigging systems.

This first diagram shows a 3:1 system with a theoretical frictionless pulley at each of the two changes of direction.

With a 100 kN load, the anchor gets 0.65 kN when you pull.

This second diagram shows a 3:1 system with carabiners at each change of direction, about 60% efficient.

With a 100 kN load, the anchor gets 0.48 kN when you pull.

So, this proves that in the real world, friction, rope, stretch, etc. decreases the load on the anchor.

Here's another way to handle that crevasse rescue scenario.

Your three person team is carrying high-efficiency pulleys, a Micro Traxion or two, and enough extra rope with each end person to be able to drop a loop down to the person in the hole.

After your buddy falls in, can you drop a loop of rope to them which they clipped to the harness with a Traxion. You also prepare the lip on top, knocking down some loose snow and putting an ice ax underneath the dropped loop to help reduce friction.

The victim, who is functional, can greatly help in this process by pulling down on one of the draft strands. This effectively reduces his weight and friction on the other strand that’s being pulled.

Now, the two partners on top can easily pull up the victim, and have a minimum load on the anchor.

To use a more extreme example, let’s say you get your car stuck in a ditch, and you rig a 9:1 with a big tree as anchor to try to pull it out. Now you have basically a tug of war between the tree and your car. When you pull onto 9:1, the anchor (in theory) gets your pulling force multiplied by 8.

Now, say someone else steps up to help you pull. How much force on the anchor components can two strong people apply? That’s now the force of two people pulling multiplied by eight. Now you’re probably getting pretty close to the safe working limits of some of your equipment. There’s a chance the weakest links on the system could start to fail, like prusiks sliding or breaking or even hardware failing. Hopefully the car moves before anything breaks or slips, but the point is, your anchor and the components of your pulley system need to be stout enough to handle these magnified forces.

So, here is the final answer - In the real world, mechanical advantage systems often result in extra force on the anchor, because of the extra effort needed to overcome friction. The greater the MA of your system, and the heavier the load you’re trying to lift, and the more friction is involved, the stronger your anchor needs to be.

This is discussed in the excellent book “The Mountain Guide Manual”, by Marc Chauvin and Rob Coppolillo, pg 276.