Alpine Tips

Convert a 1:1 to a 3:1

When hauling on a big wall a 1:1 mechanical advantage system might need a boost, if your bag gets hung up or is dragging on a slab. Here's a quick way to increase your pulling power to a 3:1.

I learned this tip from big wall ace Andy Kirkpatrick’s excellent aid climbing and big wall book, “Higher Education”. Definitely recommended for all big wallers! Connect with Andy on his website and his Substack.

A few words on hauling, from Andy Kirkpatrick:

“Hauling is potentially one of the most dangerous aspects of big wall climbing. This translates to ultra-caution in all parts of your hauling system and interaction with bags, haul lines, docking cords, and pulleys. If you rush and make a mistake, drop a load or have it shift where it's not wanted, you could easily kill someone or yourself. I try and teach climbers to view their bags as dangerous creatures, like a great white shark, rhino, or raptor that is in their charge. The ability to keep them calm and under your control comes down to paranoia, foresight, and heavy respect for the damage they can do.”

When hauling light to moderate loads on a big wall, you can hopefully use a 1:1 mechanical advantage system most of the time. Yeah, it’s gonna hurt, but it’s usually going to be the fastest. (For bigger loads, you might prefer a 2:1 haul, which we cover extensively at this article.)

However, there may be times when you want to ramp up your pulling power from a 1:1 to 3:1. Typically, this happens when the bags are temporarily hung up, or are transitioning from being pulled from space onto a slab, or something else that introduces evil friction that you need to overcome. Or, maybe you're just feeling beat from a long day and want to make your haul easier, even if it takes a little longer.

Here's one way to set this up fairly quickly. You’ll need a bit of extra gear to do this, but hey you're big wall climbing so you have this with you, right? I’m showing this with pulleys for maximum efficiency. If you don't have those, you could also do it with carabiners at each change of direction, but you're going to be losing about 50% of your pulling efficiency, so pulleys are a better choice if you have them.

The basic idea is to make a 3:1 Z drag, with the pull strand redirected to the anchor point so you're pulling down instead of up. If that didn't make any sense, look through the photos below, and think it through. Once you understand the basic concepts, it takes just a minute or two to set up.

The photos are meant to illustrate the general procedure, and not to specify the exact gear that you should use. Everyone carries different equipment; use what you have.

Like with all big wall hauling systems, you practice this thoroughly until you have it dialed, with a realistic load, in a controlled environment, with the gear you’ll actually have with you.

Safety note: If you think your bag is slightly hung up, you can try this to get it free. However, if it's really stuck, it might be a better choice to rappel down (or have your second pendulum over, if possible) and actually remove the bag from the obstacle instead of putting a really large load on your hauling system.

Here's your basic 1:1 hauling system. The rope goes through Petzl Micro Traxion progress capture pulley at the anchor. There's a toothed cam on the pulley that captures the progress of your pull; if you let go of the rope, the pig does not slip down.

The Traxion is on a locking quickdraw. The quickdraw lets the pulley twist a bit and better align itself with the direction you're pulling, which slightly increases efficiency.

The rope going through the pulley on the anchor does not create any mechanical advantage. It merely changes the direction of the pulling force, in this case downward, so you can pull the rope down with your body weight rather than lifting up with your muscles. For every 1 meter of rope pulled down on the right strand, the pig goes up by 1 meter.

Step 1: Add a sling, carabiner, and pulley to the anchor. This will become the redirect for your pulling strand. Here, I girth hitched a 30 cm sling onto the top carabiner of the quick draw. This extends the redirect pulley a bit below the progress capture pulley so they don't clank around on each other. (If you have a schweet progress capture pulley with a hole at the bottom, like the Petzl Pro Traxion, skip the sling and clip the carabiner/pulley through that hole.)

Step 2: Clip an ascender upside down onto the load strand, add a carabiner and pulley, and clip the pull strand to the pulley. Here I'm using a Petzl Rollclip, an nifty integrated locking carabiner and high efficiency pulley wheel that works great in this application. But any combination of carabiner and pulley will work.

I'm using a handled ascender because that's pretty common gear you would have with you on a big wall. You can also clip a water bottle or two onto the top of the ascender, which can help it reset itself when you give it slack between pulls. However, any kind of a rope grabber would work here.

This is now your “tractor” pulley, meaning the one that's doing the work. If you pull upwards (toward the anchor) at this point, you have a 3:1.

Step 3: Clip the pull strand through the redirect carabiner that's on the anchor. Pulling upwards is a lot of work! We want to use our body weight and pull down. The redirect lets us do that.

Schweeeet! Now we have a 3:1, redirected for a downward pull. Pulling 3 meters of rope through the system will move the pig 1 meter. We have pulleys at every change of direction, which maximizes our efficiency. Again, you could use carabiners at every change of direction, but it's going to make the pulling significantly harder because of the extra friction. (Carabiners are about 50% efficient, a good quality pulley is about 90% efficient.)

Slide the ascender as far down toward the load as you can, and then pull downward, where the glove is. If raising a large load, you probably don't want to actually be yanking on the rope with your hand. Clip the pull strand through a Grigri or ascender, clip it to your harness, and start doing squats, using your bodyweight to lift. Or, you can clip another ascender to the rope where the glove is, clip an aider onto that, and then step down on the aider with your foot to lift the load. Use body weight, not arm strength.

When the ascender and redirect pulley come together, reset the system by sliding the ascender down toward the pig, and continue lifting. To help the blue ascender slide down on its own, you can clip a few cams onto it. The extra weight should help it reset itself.

The previous photos were done horizontally to spread out the gear and more easily see how it works. Here’s the same set up done vertically, so you can see how the ropes hang in (semi) real life.

You can easily convert back to the standard 1:1 at any time, by removing the tractor and the redirect.

The 2 to 1 “Z pull” haul, explained

On a longer big wall, with bigger loads, using mechanical advantage to lift your haul bags can be extremely helpful. Here's a deep dive into the 2 to 1 hauling system.

Credits for this idea, as best I can. The 2:1 Z pull haul is generally attributed to Chongo, a legendary Yosemite dirtbag who was famous for extended vertical camping trips on El Capitan with ridiculously large loads. Pete Zabrok, also no stranger to multiple week outings on the captain with huge loads, popularized it via a 2004 Tech Tip in Climbing magazine, and now climbers such as Mark Hudon have refined it further.

This technique is explained nicely in the comprehensive aid climbing manual “Hooking Up, by Pete Zabrok and Fabio Elli, highly recommended for all big wall climbers!

A few words on hauling, from the excellent book “Higher Education” by Andy Kirkpatrick.

“Hauling is potentially one of the most dangerous aspects of big wall climbing. This translates to ultra-caution in all parts of your hauling system and interaction with bags, haul lines, docking cords, and pulleys. If you rush and make a mistake, drop a load or have it shift where it's not wanted, you could easily kill someone or yourself. I try and teach climbers to view their bags as dangerous creatures, like a great white shark, rhino, or raptor that is in their charge. The ability to keep them calm and under your control comes down to paranoia, foresight, and heavy respect for the damage they can do.”

Think before you act. Before you connect or disconnect anything, always think a step or two ahead and anticipate what will happen and potential problems. “If I untie this docking cord, then the load is going to go there, and after that happens, I’m going to do this . . . ”

On big wall climbs taking two or three days with a team of two, you can probably use a traditional 1:1 hauling system. However, for climbs much longer than this, or a team of three, or when you or your teammate are significantly lighter than the bags, or if the hauling is on terrain less then vertical, or maybe when you simply want to suffer a lot less, you may well want to add some mechanical advantage. As the saying goes, you can work hard, or you can work smart. For a big load, a 2:1 haul is working smart. (If you’re taking a truly ridiculous amount of stuff and need a 3:1 or 4:1, you're probably an expert enough climber to figure that out on your own, so I'm not going to cover that here.)

Say you have a pair of haul bags that together weigh 200 pounds. If you rig a 2:1 haul, you (theoretically) can lift this load with only 100 pounds of force. The catch is, you have to pull twice as much rope in order to get the load to the anchor, but for many people that’s a fine trade off to make. Think of it this way: do you want to lift 200 pounds once, or 100 pounds twice?

Now, there is Google-load of information out there about 2:1 haul systems. But like most things on the interweb, especially discussion forums, the signal to noise ratio is not so great; you’ll have to wade through pages of the usual randomness to get anything worthwhile.

Well, good news you you, I’ve taken care of the sorting and sifting. This post is a summary of current (2020) best practices, clear photos, and some specific gear reccos for the 2:1 big wall haul.

I’ll be honest, the first time I saw this I found it pretty darn confusing, and wondered if it was really worth it. But once you get the components arranged correctly, and give a little thought to what is happening, and try some real world testing, you’ll get the hang of it. And, hopefully you will never have to use that all too common excuse for bailing, “The bags were too heavy . . .”

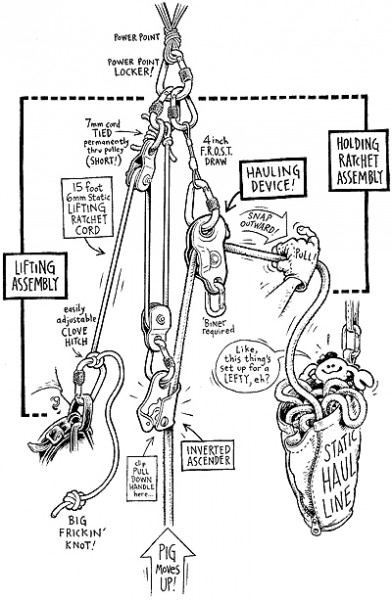

One of the best climbing diagrams ever made, IMHO. Drawing by Mike Clelland, first published in Climbing magazine (March 2004) article written by Pete Zabrok. Note, while the system has been refined in several areas since it was first published, this is still the core idea.

image credit: Mike Clelland

Big picture concepts:

Minimize stretch wherever possible

Use high quality/efficiency pulleys

Lift the load by doing squats using your body weight or pushing down with your legs, not by pulling with your arms

Practice a lot with real loads

Get it set up fast and haul the bags a few meters off the lower anchor ASAP so your follower can get to work

The basic set up is a 1:1 haul through a progress capturing pulley, such a Petzl Traxion. (This is a pulley that has a one-way rope grab on it like an ascender, that let you pull the rope through one direction but prevents it from sliding back.) Yes, these little suckers are expen$ive!

On the load strand of the haul line, you add on an entirely separate 2:1 lifting system. You raise the load with the 2:1 lifting system, and then pull the slack rope through the progress capture pulley.

In the rigging world, this is sometimes referred to as a “pig rig”, because you are “piggybacking” a 2-1 system on top of the main loaded rope. (And, that’s an entirely appropriate name for big wall climbing, because haul bags are affectionately known as “pigs”.)

General diagram of a 2:1 “pig rig”. (The black rope is the main static haul line. The gray cord is the 2-1 “Z cord.” Tilt your head to the left; it looks like a letter Z, get it?)

In the diagram below, the system is spread out over two anchors. It also works fine on one.

(Note: if you've taken a crevasse rescue or rope rescue class, you might think of a “Z drag” as being a 3:1 mechanical advantage. That is correct. However, in this case, the “Z” is a 2:1 system, with a change of direction pulley, as you can see below. Trust me, it's 2:1, don't let the “Z” in the name confuse you.)

Here's how it works.

The hauler pulls down on the gray cord, maybe by squatting in the harness.

This lifts the black rope, creating slack.

Pull that slack through with your hand, capturing the progress with the pulley on the right anchor.

Repeat!

Image credit: Andy Kirkpatrick, from his excellent book “Higher Education”, used with permission

There are various ways to rig a 2-1 haul. Here's one.

Components

All parts live in a designated small stuff sack and stay clipped together between hauls, ready to deploy.

Large HMS locking “master point” carabiner

Short Dyneema dogbone quickdraw runner (hard to see in the photo, sorry.) Zero stretch, important! This could also be a large stopper or custom made metal quickdraw. This allows the carabiner and progress capture pulley below it (3 & 4) to rotate and align when pulling.

Locking carabiner

Progress capture pulley, here a Petzl Mini Traxion

The “tractor” pulley, so called because it’s doing the work

Quicklink, I think 8mm

Inverted ascender, here a Petzl Croll. Could be a Petzl Basic or similar small ascender without a handle.

The haulbag(s), aka “the pig”

Haul line, typically 70 meter, 10 mm, static rope

Handled ascender. Add this to the “pulldown” side of the haul line to make it easier on your tired wall hands. But remember, you want to be doing most of the hauling with your bodyweight and not your arms.

The Z cord - 7 mm cord, start with about 5 meters. If you find you have too much extra cord, trim some off. Could be a thinner 5.5 mm static spectra cord for a slightly more efficient pull. Be sure and tie a large stopper knot on the end to prevent your hardware from sliding off accidentally. (Pro tip, bring a second spare Z cord, in case the first one gets trashed.)

The “redirect” pulley, so called because redirects the Z cord downwards so you can use your body weight to lift. This pulley does not add any mechanical advantage. This should be a high quality pulley, see examples below.

Small loop of 11/16” webbing tied through the pulley. This webbing connection, rather than a carabiner, allows the redirect pulley to freely rotate and give a more efficient pull. It’s important to have this webbing loop small so the redirect carabiner is high, which gives you a longer, more efficient pulling stroke.

Not shown: Two carabiners with rounded cross sections on your belay loop. When you’re hauling, you can clove hitch the orange Z cord to both of these carabiners. Having two of them makes untying the loaded clove hitch easier. Old school oval carabiners work fine.

Another option is to clip an ascender with a stirrup of webbing or an aid ladder onto the Z cord, and pump down on the Z cord with your leg.

Here’s another way to rig this. Note the redirect pulley (orange) with an integrated swivel, smaller diameter static Z cord, a cable quick draw (zero stretch) and a Petzl Basic ascender. This looks a little simpler without the haul rope, but it's the same basic idea.

image: https://www.mountainproject.com/forum/topic/115790897/the-latest-greatest-21-hauling-kit

Side note: You might be tempted to use a rigging plate clipped to the master carabiner, because it has three things clipped to it and it's getting kind of busy. This would be a mistake. Reason being, that rigging plate is going to rock back-and-forth as it's loaded and unloaded on different sides, which will decrease your hauling efficiency.

Rigging plate - Do NOT use it in your 2-1 hauling system.

One of the beauties of the 2 to 1 haul kit is that you can set it up pretty much once, keep most of the components clipped together in the correct order, and leave it that way. It has its own small designated sturdy stuff sack (medium sized Fish “Beef Bag” works great). The haul kit is never taken apart, and is either being used or in the storage bag. Note that the hauling system hardware always stays clipped to the storage bag; can’t drop the bag if you do this.

Note that the leader does not have to take the haul kit up with them on lead. The leader can trail a tagline, and bring up the haul kit once they arrive at the anchor. Doing this saves weight and cluster on your harness. More on using taglines here.

At the belay, here’s what you do:

Build an equalized master point anchor from 2 bolts. (If the bolts look newish and extra stout, you can haul off just one, but I’ll leave that choice to you. Me, I like 2 bolts.) Use an “anchor kit” of several large locking carabiners, and maybe a pre-tied quad anchor or PAS that you and your partner can set up fast and the same way pretty much every time.

Clip the master point carabiner for the Z haul system to the anchor master point (or lone hauling bolt).

Run the haul rope through the progress capture pulley, engage the cam, and pull all the slack through the pulley. Then clip on the inverted ascender. Hopefully you have a rope bag; now would be a good time to start using it to stack the haul rope.

Extend your daisies or connection to the anchor so you are free to move. Find yourself a good stance and adjust the Z cord with the clove hitch on your harness. (Altenatively, clip an ascender to the Z cord, clip on an aid ladder, and press down with your leg.)

Start lifting your bags a few meters, so your partner below can get busy breaking down the anchor. (Once the bags have been lifted off the lower anchor, ONLY THEN you can take a break for a minute or two before you start the real hauling.)

A few notes . . .

As pointed out to me by wall ace Mark Hudon: Yes, you may be theoretically 2:1 efficient, but that can also mean 2:1 inefficient. Meaning, if you have 1 inch of slack in your lifting system, you’re actually losing 2 inches of lift with every stroke. When you push the lifting ascender down, be sure to Z cord comes tight to the clove hitch to your harness so there is no slack. Squat with your body weight. If you doing it right, there should be no pulling or lifting with your arms at all.

Practice, practice, practice with this system. Go find a retaining wall, a tree, a fire escape, an outside staircase, whatever, and load up a haul bag with water bottles or bricks or rocks, and really give it a work out. Which way should the master carabiner face (left or right off the bolt hanger) to be most efficient for you? Do you want to have the inverted ascender by your dominant hand or your weaker hand? How long exactly should the Z cord be? (This changes depending on your stance.) These are some subtle yet important adjustments that can only be found with practice. Taking the time to dial in your system will pay big dividends on the wall.

It's usually less energy to do more small squats than fewer big ones. Doing short little strokes might seem like it's gonna take forever, but you're probably going to expand less energy in the long run.

Ideally, you want your strong/dominant hand on the inverted ascender, and your weaker/non-dominant hand pulling the slack rope through the progress capture pulley. So, in the cartoon diagram at the top, and the labeled photo, this is set up for a left handed person. Experiment with this and see what work for you.

Ideally, both pulleys should be high efficiency, with sealed ball bearings with 1.5 to 2 inch aluminum sheaves/wheels. These will cost about $40 each, don’t skimp on these. If you have one pulley that’s better quality and/or has a larger diameter wheel, use this as as redirect pulley, and use the smaller or lower quality pulley on the tractor. The reasons for this get into some engi-nerd territory, but trust me, this is the best way to rig it. (But, don’t be a cheapskate, just spend an extra 10 bucks or so, get two high quality pulleys, and then it’s not an issue at all.)

When shopping for pulleys, go for quality from major manufacturers such as SMC, Petzl or CMI; they are used a lot by professional riggers and rescue teams. Look at the technical specifications. Stay away from cheaper pulleys that have plastic wheels (aka sheave) or bronze or nylon bushings. You want an aluminium sheave and sealed ball bearings. A small inefficiency in a pulley is magnified many thousands of hauling strokes over a single route, so the difference between say 70% and 80% efficient is significant. Fortunately you can have lightweight, high efficiency pulleys, you just need to buy the right ones.

Mark Hudon likes the 2" Single PMP and the Micro Single PMP, both made by SMC (Seattle Manufacturing Company). Some other good options would be the Petzl Rescue pulley or the CMI RP102.

Prusik minding pulleys (also known by the acronym of PMP) tend to be more expensive that regular pulleys. You don’t need a PMP in this system, because there are no prusiks.

When hauling, remove everything from your harness gear loops. You want to minimize extra weight when you’re repeatedly squatting and standing.

Bring a spare Z cord. If you're doing this over a ledge, the cord might get damaged. Bring a spare.

Practice will not only help you haul more efficiently, but it will help you get set up faster. This is important, because your partner can’t start to break down the anchor and begin cleaning until you haul the bags at least a meter or two and get them off the previous anchor.

If the leader wants to be extra courteous and helpful, they can break down the hauling kit when the bags are safely docked, package it back up in its stuff sack, and hang it on the first piece of gear for the next pitch, so the new leader can be sure and grab it. (If the second is using a tagline to pull up the kit when they need it, then no need to hang it on gear for the next pitch.)

Just like with any hauling system, you want to minimize friction in any way you can. If you have the option, build your hauling anchor as high up as possible, and try to eliminate or minimize the angle at which the rope may run over any rock edges. If the pitch is overhanging, lucky you. If you're pulling the bags up a slab, then you're theoretical 2:1 is going to act more like a 1:1. Prepare to suffer.

Wear gloves for big wall hauling. The Metolius 3/4 finger climbing gloves are great.

Here’s a video of Mark Hudon using this system to haul a big load on the first day on El Cap. Keep in mind Mark weighs about 130 pounds, but look at the great rhythm he has with the pull.

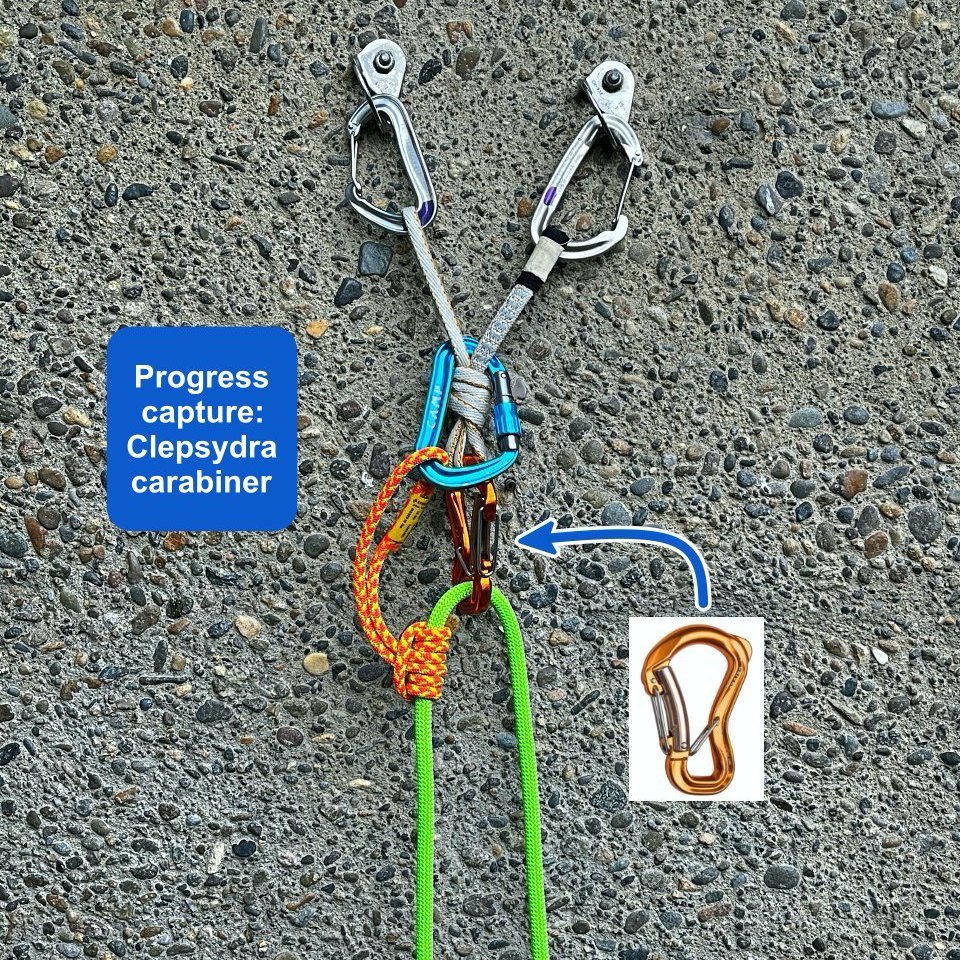

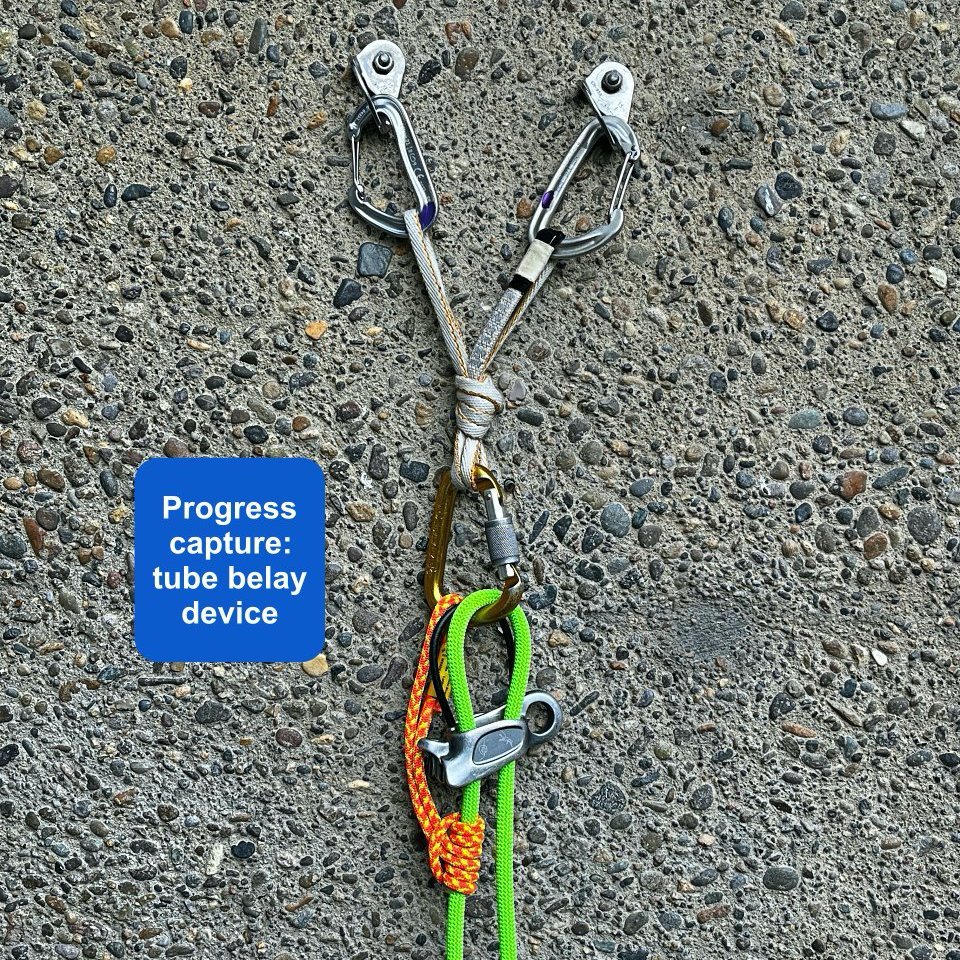

Improvised progress capture

Sure, a svelte progress capture pulley in a hauling system (such as a Petzl Micro Traxion) is great. But if you don't have one, a quick link, captive eye carabiner, or belay device can help keep your prusik loop in place in a hauling system. And let's not forget the big wall favorite, an ascender.

In most any kind of hauling system, you need a way to capture the progress of your hauling, so the load doesn’t slip when you ease up on your pulling.

Sure, it’s great to have a nice progress capturing pulley like a Petzl Micro Traxion) every time you might need one, or maybe a prusik minding pulley. But, dang, those little suckers are expensive! Plus, often in a self rescue situation, you need to improvise and adapt with the gear you have available.

Another option is the so-called “prusik minding” pulley. This is a pulley with the narrow “sidewalls”. This means that the prusik catches on the pulley, and doesn’t get sucked into it. Yes, these work well, but for some reason they seem to cost about twice as much as a standard pulley. I don't understand this at all, and that's why I don't own one nor recommend them.

Here are a few methods.

In all the photos below, the load strand is on the left, the pull strand is on the right.

In most of the photos below, I’m using a carabiner rather than a pulley. Pulleys are better to reduce friction but minimalist climbers do not often have one.

1 - Quicklink

Add a quicklink to both rope strands as shown, above the prusik. This keeps prusik from getting sucked into the carabiner.

The success of this depends on quicklink size, rope diameter, prusik diameter, etc. Like with all self rescue techniques, be sure and test this at home before you rely on it in the field. (And yes, I get it that quicklinks are a heavy, single use piece of kit that some people choose not to carry. You’re especially unlikely to have one on a glacier climb.)

2 - Captive eye carabiner (here, a Grivel Clepsydra)

That tiny end of that carabiner that fits nicely around your belay loop? That also does a nice job of keeping the prusik hitch from pulling through.

I love this carabiner for glacier travel. Your carabiner never gets cross loaded, which can be important when you're clipped to the rope rather than tying in to the rope, the double gate design means it will never freeze shut or wiggle open, and it does extra duty as shown below if you need it.

3 - Belay device

Use a tube style belay device such as a Black Diamond ATC. However, this has a few downsides.

You have to be clever enough to install it when you’re building your system; you can't put it on after the rope is loaded. The benefit of the quicklink is that it can be added after the rope is loaded.

You just “lost” your ATC into the hauling system. Generally it's best to keep important personal gear available if possible in case you have to use it later.

For moderate glacier travel, many people choose not to bring a belay device at all. So you may not have one when you're most likely to need it. But for other hauling situations, it works pretty well.

4 - Ascender

Here's one for the aid climbers, who are likely to have a pulley and an ascender. Before progress capture pulleys were invented, this was the standard hauling method on big walls.

This looks like the rope is getting twisted as it goes through the pulley. In fact, once you put a load on it, the pulley and ascender line up quite nicely.

Mechanical advantage calculator from alpinerecreation.com

Here's a link to a very cool online mechanical advantage calculator! Choose your rigging method, choose your components, choose your load, click a button, and you instantly see all of the different forces in the different legs of your rigging system. Courtesy of the New Zealand-based guiding company, alpinerecreation.com.

I recently came across this clever online tool from alpinerecreation.com, a New Zealand based guiding company.

It’s a mechanical advantage calculator, very cool!

This is an excellent way to instantly see some of the forces involved with different rigging methods, and how using a carabiner rather than a pulley can change the efficiency of your system.

(Works fine on a mobile phone but it's easier to see the big picture on a wider computer screen.)

Choose your hauling system (2:1. 3:1, 5:1, 6:1, etc.)

Choose your components (Micro Traxion, rescue pulley, large carabiner, small carabiner, etc.)

Choose your load (default is 100 kg)

Choose your units (percentage of load, kg, or kN)

Press “Calculate” and it gives you values and forces all the way through the system!

Here’s a screen grab showing values for a 3:1 Z drag, using a Micro Traxion as the progress capture and a good quality pulley on the “tractor”.

image: https://www.alpinerecreation.com/mechanicaladvantagecalculator.html

Can you have "too much" mechanical advantage?

A good general rule: use the least amount of mechanical advantage (MA) that you can to get the job done. Adding additional pulleys and ropes grabs also introduces more friction. In some cases, what you think is giving you extra MA may actually be worse than what you had before.

A good general principle in setting up mechanical advantage (MA) systems: use as little as you need to get the job done. Are you able to move your load with a 3:1? Great, use that, and don't make it a 6:1!

Or, to put it another way, just because you CAN add more MA doesn't mean you SHOULD add more MA.

Every time you increase mechanical advantage:

You add extra gear, changes of direction, introduce more friction, and create more chances for ropes to twist, rub, cross etc. that reduces the overall efficiency

You increase the force on the anchor

A fundamental principle of economics (and many other aspects of life, including climbing) is the law of diminishing returns. In econ-speak, means that adding additional factors of production eventually results in smaller increases in output. Say that it takes one builder one year to build a house. So, if you have 365 builders, can you build a house in one day? Of course not, because after a certain point, the extra production (builders) result in lower output (less work getting done because they are tripping over each other).

MA systems work in somewhat the same way. Past a certain point, it doesn’t make sense to keep adding components to the system, because you're actually decreasing efficiency.

Here's an example, with a common self rescue techniques taught in many books and classes.

You’re belaying your second with a Grigri off the anchor. They get to the hard part, and need a short lift / assistance to get past a hard move or two.

No prob! You set up a theoretical 3:1 as shown on the left. Simply add a rope grab on the loaded rope going down to them, clip a carabiner onto the rope grab, and pull up. Voilà, a nifty 3:1! Start pulling and up they go, right?

Well, not quite! Let's have a closer look at the top photo.

Because you’re using a fairly inefficient carabiner (about 45% efficient) and a really inefficient Grigri (about 28% efficient) as your progress capture, at every change of direction where the rope goes through these devices, they are going to rob you of some of your pulling force. This means your real world efficiency is somewhere around 1.6 to 1, not 3 to 1.

Depending on your strength and the rope running over any edges or gear and adding additional friction, etc. might mean it's still impossible to move your partner!

No problem, let's make it a 5:1!

“Wait”, you say, “I know what to do! I have another rope grab. I’ll put that on the backside of the rope coming from the Grigri, and clip my pull strand to that. Now I have a 5:1 pulley system! With that I should surely be able to lift my lard-ass partner. Besides, now I get to lift DOWN with my body weight instead of UP with my arms. That must be easier, right?”

Well . . . Let's have a look at the photo on the right.

Turns out, rigging a theoretical 5:1 like this gives you something pretty much close to a 1:1 in real life! That red carabiner on the rope grab introduces so much additional friction at the start of the system, that the rest can't really overcome it. You probably be better off staying with that 3:1.

You have also created what's called a “complex” pulley system. In a complex system, you have two pulleys moving toward each other when you pull. This can be a bother when you’re at a small stance, and requires that you reset the system more often.

There are some good ways to set up a 5:1 or a 6:1 at a small stance that require minimal gear and offer reasonable efficiency. Unfortunately this is not one of them.

So, if you build a lame hauling system like this and it's not working . . . you need to yell down to your partner to get out a couple of their own friction hitches and start prusiking up. =^)

Takeaways:

There can be a giant difference between theoretical MA and a real world MA.

Adding more MA is not always better.

Use pulleys when possible to increase your efficiency.

If you have a limited pulleys, use them closest to your hand that’s doing the pulling.

The three types of mechanical advantage

Mechanical advantage (MA) systems have been described as like a blind date: what’s promised is always better than what's delivered. There can be a significant difference between theoretical, calculated, and real-world mechanical advantage. Learn what these are and see some examples.

This article has some diagrams made with the very cool rope rigging software, vRigger.

Use discount code “ALPINESAVVY” to get 10% off vRigger software.

Short version : sort of like a blind date, the mechanical advantage you’re hoping for is never as good as what was promised. =^)

Mechanical advantage (MA) systems are typically described with a nice, tidy number, like 2:1, 3:1, or 6:1. In theory, this means with a 3:1 system, one unit of input force (that’s you pulling on the rope) results in three units of output force that gets applied to the load.

So in theory, with a 3:1, you can move a 100 kg load by pulling with only 33 kg of force. Wouldn't that be nice!

While this is a convenient number to generally describe an MA system, unfortunately you’ll never achieve that in real life. Why?

There actually three different flavors of MA that need to be considered:

Ideal

Theoretical

Actual

Let’s have a look at each one.

Ideal MA

With a 3:1 system, you need to pull 3 meters of rope through the system to move the load 1 meter. With a 6:1 system, you need to pull 6 meters of rope to move the load 1 meter. Pretty simple idea, right?

Unfortunately this would only be true in an imaginary universe with no friction. While the ideal MA is useful for generally describing a system, it doesn’t tell you much about the pulling force that’s actually applied to the load. So for now, we’ll step away from it.

Theoretical MA

In the real world, every time the rope changes direction, friction enters the system. Your pulling energy, instead of being 100% transmitted along the rope, is converted to heat from the friction, and this heat is lost to the atmosphere. With a good quality pulley this friction will be minimal. With a carabiner this friction is substantial.

The term used to describe friction in rigging systems is efficiency.

A good quality pulley is around 90% efficient. That means that 90% of your pulling force gets moved through the system and you only lose 10% to friction. That's good! On the other hand, using a carabiner, which is about 50% efficient, means that you lose 50% of that input force to friction, and only half of it comes out the other side of the carabiner. That's not so good!

By using a technique called the “T method”, it’s fairly easy to calculate the friction involved in your system to get a more realistic view of the “pull” needed to move your load.

Here’s a quick example of the T method on a 2:1 system, one with a pulley and one with a carabiner. (This diagram was made with a very cool software, vRigger.

Use discount code “AlpineSavvy” to get 10% off vRigger software.

When you start looking at Theoretical MA, things get interesting!

On the left, using a high-efficiency pulley on the load, you need to pull with less force, but you also have a higher load on the anchor.

On the right, with a low efficiency carabiner on the load, you need to pull with more force, but that puts a lower load onto the anchor.

images made with vRigger

Have another look at “El Puerco” at the top of the page. Both set ups are for a theoretical 3:1.

The one on the left is set up with good quality pulleys at every change of direction. With that, you get about the best possible MA of 2.7 to 1.

However, the system on the right, which is one often improvised by climbers with minimal gear, introduces a lot more friction into the system from the Grigri and carabiner. This gives a rather pathetic calculated MA of 1.65 to 1. Big difference!

Side note: Do mechanical advantage systems magnify load on the anchor?

An MA system, in theory, does not magnify the load on the anchor. At the theoretical level, with a simple system like a 2:1 or 3:1, you're never going to apply more load on the anchor then the weight of your load.

At rest, the anchor sees the weight of your load.

When you're pulling, you are supporting some of the load with your hand, so that gets subtracted from the load on the anchor.

However, when you start adding in real world factors, such as friction of the rope running over an edge, forces can start to become higher than the load. But, at a theoretical level, it's important to know that the MA system itself does not magically increase anchor force.

Actual (aka real world) MA

Finally, there’s the third flavor of mechanical advantage, actual.

Actual MA is the actual result of all the messy and hard-to-quantify variables encountered when actually trying to pull something. For example:

the rope running over a ledge or through climbing protection (LOTS of friction can come from this; ledges are bad)

rope strands that cross, are twisted or rub (try to minimize this)

whether your rope is dynamic or static (static is better)

Whether your rope sheath is old and crusty or new and slippery (slippery is better)

the diameter of the rope (smaller is better)

the diameter of your pulley wheel (larger is better)

the angle of your pulling hands relative to the anchor (try to pull in line with the other rope strands)

So, squirrely things like that! You might have calculated your MA with the T method perfectly, but when you start introducing some of these other factors into your system, your real world MA decreases even further. About the only way we can measure this is using scales and load cells with a real load.

So, the takeaway: theoretical MA will always be greater than calculated MA, and calculated MA will always be greater than real world MA.

The 3:1 Spanish Burton haul system

After you have the basics of a 2:1, 3:1 and 6:1 hauling system dialed, rope geeks and mechanical advantage fans might want to learn some more esoteric rigging. Here's one of them, the 3:1 Spanish Burton. It lets you pull down, instead of up, which could be helpful in a vertical haul. Practice with it, it's fun!

When learning mechanical advantage for rope rescue, I think it’s important to start with the basics: a 2:1 “C” and a 3:1 “Z”.

Once you have those dialed, one can be added on top of another one to create what’s called a compound 6:1 if you need extra pulling power.

In just about every rope rescue scenario, some combination of a 2:1, 3:1 or 6:1 should cover all of your needs.

However, if you like playing around with ropes (and I know you do, otherwise you wouldn't be reading this) here’s an interesting one to learn: the 3:1 Spanish Burton.

(No, I have absolutely no idea why it’s called the “Spanish Burton”. Guessing it had to do with a guy named Burton who found himself on a Spanish sailboat about 400 years ago . . . )

Why might the Spanish Burton be applicable in rope rescue?

In a vertical lift, you can pull DOWN with your body weight to lift the load. (In a more typical 3:1 Z drag, you need to pull UP.) For a vertical lift, it's helpful to have the anchor point as high up as possible so you can use your body weight most effectively.

It lets you set up a 3:1 with basically zero extra rope. Such as, you're only carrying a meter or two of extra rope, your partner falls in a crevasse, and you need to set up a 3:1. (Yes I know, not super-practical, but could be helpful.)

Spanish Burton rigging notes . . .

The purple sling is tied to the green rope with a Klemheist hitch. You could also use another rope grab here, like a Tibloc. (I used a sling here; any bit of cord or sling will work.)

The 120 cm purple sling means you need to reset the system often. If you have more room to work, you could replace this with an untied cordelette, which would give you a much longer pull.

The always handy Petzl Micro Traxion is the progress capture pulley on the anchor.

We have two “traveling” rope grabs moving toward each other. This means you need to reset your system more often, which can be a hassle if you have a small workspace, or no big deal if you have a large area to work in, like on a snowfield.

Note that the Spanish Burton increases the load on the anchor. For example, if you pull with 1 “unit” of force, this puts a load of about 4 “units” on the anchor. Compare this with a traditional 3:1 Z drag. With a Z drag, if you pull with 1 unit of force, you have 2 units of force on the anchor. If your anchor is unquestionably strong, no worries. If it's not, this may be something to consider.

Using the “T method” to determine the mechanical advantage

There's a technique called the “T method”, or the tension method, which can determine the mechanical advantage of many rigging systems.

We start with an input force of 1, that's your hand pulling on the purple sling.

At the blue pulley, the input force is doubled to 2. That gets transmitted to the prusik hitch, and to the green rope.

The 2 on the green rope goes into the Traxion. That is doubled for a total force of 4 on the anchor.

The input force of 2 comes out of the Traxion on the other side as 2.

This force of 2 travels down the green rope on the load side. There, it meets the force of 1 on the left side of the purple sling.

You add those together for total mechanical advantage of 3:1.

If you want to learn more about this, here’s an excellent tutorial video on how to count tensions using the T method.